Setting up a groundnut oil manufacturing plant requires multiple steps and conditions, and requires proper planning and investment. Here is a comprehensive overview of what you will required to set up a groundnut oil manufacturing plant:

(1) Market Research: Understand the demand for groundnut oil in the market, competition and potential customers. Analyze competitors, price trends and consumer preferences.

(2) Business Plan: Develop a comprehensive business plan that includes financial projections, cost analysis and the groundnut oil manufacturing plant’s operational plan.

(1) Industrial License: Obtain necessary industrial permits from local and national authorities.

(2) Food Safety Certification: Groundnut oil is a food product, so obtaining certification from the Food Safety and Standards Authority (or equivalent) is crucial.

(3) Environmental Clearance: Depending on the location and scale of the groundnut oil manufacturing plant, you may need environmental clearance for waste disposal and emissions.

(4) Trade License: A trade license is required for the legal operation of the groundnut oil manufacturing plant.

(1) Land: Choose an industrial zone or location that has access to raw materials (groundnuts), transportation (for groundnuts supply and product distribution), and utilities (water, electricity).

(2) Building Construction: Plan the layout of the groundnut oil manufacturing plant, which includes areas for groundnut oil processing, storage, packaging and waste management.

(3) Storage Facilities: Adequate storage facilities for raw materials (groundnuts) and finished products are needed.

(1) Raw Materials (Groundnuts/Peanuts): The primary raw material for groundnut oil manufacturing plant. Ensure a steady supply of high-quality groundnuts/peanuts.

(2) Packaging Materials: Bottles, labels, caps, cartons, etc., for the final product.

Raw materials (groundnuts/peanuts)

Raw materials (groundnuts/peanuts)

(1) Groundnut Pretreatment Equipment: In order to meet the requirements of groundnut oil manufacturing process, the use of groundnut pretreatment equipment is very important. Usually includes groundnut shelling equipment, groundnut cleaning equipment, groundnut crushing equipment, groundnut flaking equipment and groundnut roasting equipment.

Groundnut pretreatment equipment

Groundnut pretreatment equipment

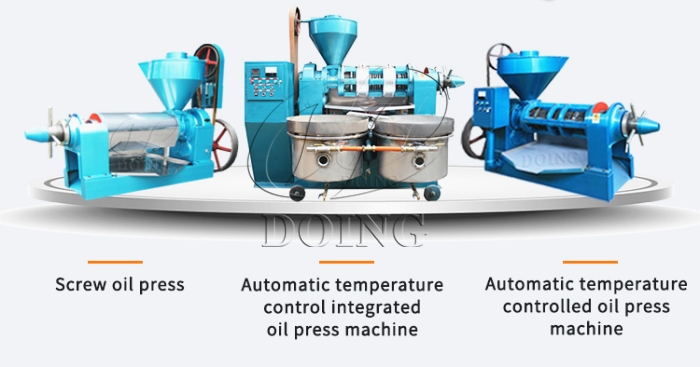

(2) Groundnut Oil Expeller/Pressing Equipment: To extract the oil from the groundnuts.

Groundnut oil expeller/pressing equipment

Groundnut oil expeller/pressing equipment

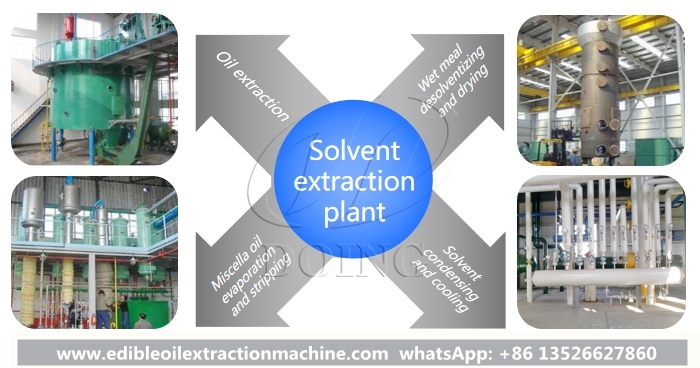

(3) Groundnut Oil Solvent Extraction Equipment (Optional): For higher groundnut oil manufacturing efficiency, a solvent extraction process can be used in addition to the mechanical pressing.

Groundnut oil solvent extraction equipment

Groundnut oil solvent extraction equipment

(4) Groundnut Oil Refining Equipment: To remove impurities from the extracted crude groundnut oil (e.g., degumming, deacidification, decolorization and deodorization).

Groundnut oil refining equipment

Groundnut oil refining equipment

(5) Groundnut Oil Packaging Equipment: For filling and sealing bottles or containers with refined groundnut oil.

Groundnut oil filling equipment

Groundnut oil filling equipment

(6) Quality Control Lab Equipment: To ensure the groundnut oil meets safety and quality standards.

(1) Skilled Labor: Hire skilled professionals, including engineers, technicians and quality control experts. Provide training to your workforce to operate groundnut oil manufacturing equipment and maintain quality standards.

(2) Management Team: Assemble a strong management team with experience in food processing, logistics, sales and marketing. Effective leadership is essential for the smooth operation of the groundnut oil manufacturing plant.

A stable and sufficient power supply is essential for the operation of groundnut oil manufacturing plant. In addition, consider having a generator or backup power source in case of power outages.

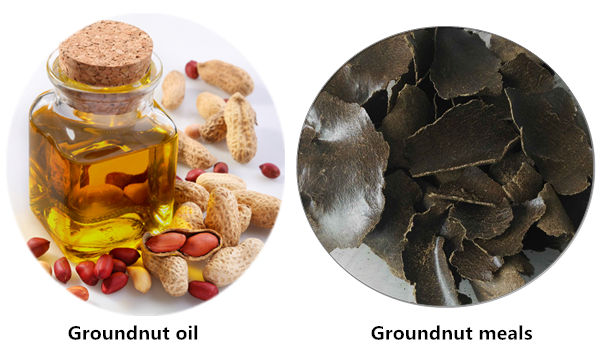

Install systems for waste disposal, groundnut oil filtration and water treatment to ensure the groundnut oil manufacturing plant operates sustainably and complies with environmental regulations. Besides, manage the by-products like groundnut cake or meal that can be sold as animal feed or used in other industries.

Groundnut oil and groundnut meals

Groundnut oil and groundnut meals

(1) Capital Investment: Ensure sufficient capital for the purchase of groundnut oil manufacturing equipment, construction of the groundnut oil manufacturing plant and operational expenses.

(2) Operational Costs: Ongoing costs for raw materials (groundnuts/peanuts), labor, utilities and marketing.

To sum up, setting up a groundnut oil manufacturing plant is a complex but rewarding undertaking. By carefully planning each step, you can build a successful and sustainable business that meets the needs of consumers while contributing to the economic development of your region. If you need groundnut oil manufacturing equipment support for setting up a groundnut oil manufacturing plant, please contact Henan Glory Company(with branch and overseas warehouse in Nigeria). We are a manufacturer specializing in the production of groundnut oil manufacturing equipment and can provide you with professional customized solutions!