Home > FAQ What are the advantages of thermal oil heating compared with electric heating edible oil refining equipment?

Home > FAQ What are the advantages of thermal oil heating compared with electric heating edible oil refining equipment?

In edible oil refining equipment, both thermal oil heating and electric heating are commonly used methods for providing the required heat. However, each has its advantages depending on the specific needs of the edible oil refining process. Below are the advantages of thermal oil heating edible oil refining equipment compared with electric heating edible oil refining equipment:

Thermal oil heating edible oil refining equipment is generally more energy-efficient for high-temperature processes. The thermal oil, often heated by a boiler or a furnace, can maintain a consistent and high temperature without significant loss of heat, which is beneficial for continuous edible oil refining process. In addition, thermal oil heating allows for more effective heat transfer across the edible oil refining equipment, leading to reduced energy consumption compared to electric heating, which may require more energy to reach high temperatures.

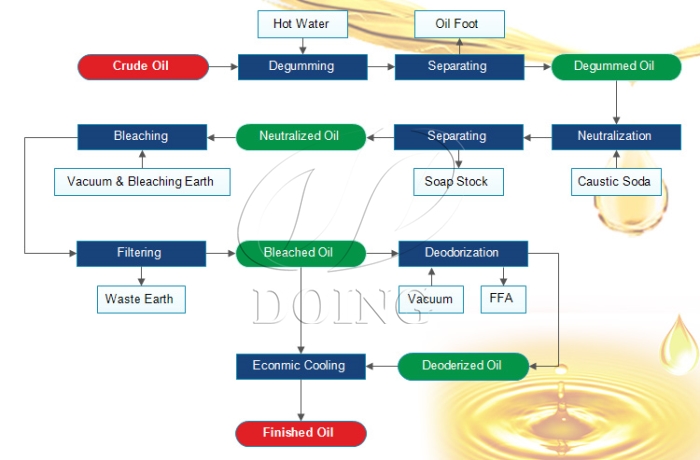

Thermal oil can circulate throughout the edible oil refining equipment, providing a more even and consistent distribution of heat. This is especially important in edible oil refining process like degumming, deacidification, decolorization and deodorizing, where uniform heat is necessary to maintain optimal conditions and avoid uneven processing.

Edible oil refining process

Edible oil refining process

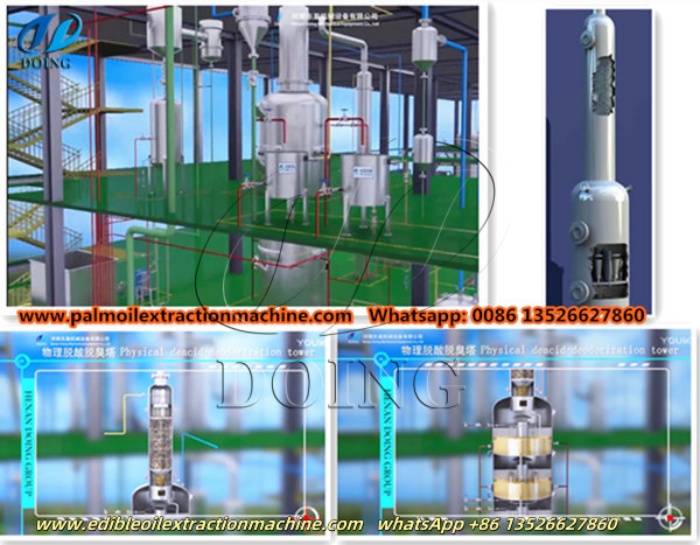

Thermal oil heating can easily achieve and maintain higher temperatures compared to electric heating edible oil refining equipment. This is particularly important for edible oil refining process that require high and stable temperatures, such as deodorization (typically around 230°C to 270°C). Electric heating edible oil refining equipment, in contrast, may struggle to reach or maintain these high temperatures efficiently and consistently over time.

Edible oil deodorization equipment

Edible oil deodorization equipment

For large-scale edible oil refineries, thermal oil heating edible oil refining equipment are typically more cost-effective in the long run because they are suitable for high-temperature processes and can handle large volumes of heat with a low operational cost. Electric heating edible oil refining equipment can become expensive due to high electricity consumption, especially for large operations.

Thermal oil heating edible oil refining equipment offer better control over temperature regulation and allow for precise adjustments based on the needs of different stages of the edible oil refining process. Besides, the thermal oil, which remains stable at high temperatures, makes it easier to control the temperature within a defined range for each process step.

Thermal oil heating edible oil refining equipment are generally more robust and durable than electric heating edible oil refining equipment, especially in high-temperature environments. This translates to lower maintenance costs over time. In contrast, electric heating elements can degrade or burn out faster under high-temperature conditions, leading to more frequent repairs and replacements.

Thermal oil heating edible oil refining equipment

Thermal oil heating edible oil refining equipment

Thermal oil heating edible oil refining equipment is a ideal for continuous, high-volume production in the edible oil industry, where consistent heat is required over extended periods. Electric heating edible oil refining equipment may face limitations in maintaining continuous high heat over extended periods without substantial energy costs.

In conclusion, thermal oil heating edible oil refining equipment is often the preferred choice for edible oil refining in large-scale operations, especially when high temperatures and efficient heat distribution are needed. Electric heating edible oil refining equipment, on the other hand, may be more suitable for smaller-scale operations or where precise control over lower temperature lower temperatures is required. The choice between thermal oil heating edible oil refining equipment and electric heating edible oil refining equipment ultimately depends on the scale of production, energy costs and operational requirements of the edible oil refinery plants. If you want to know more about the advantages advantages of thermal oil heating compared with electric heating edible oil refining equipment or are interested in the two types of edible oil refining equipment, please feel free to contact the Henan Glory Company(with branch and overseas warehouse in Nigeria) and our professionals will provide you with scientific knowledge and equipment introduction.