In the edible oil refining process, achieving the high quality edible oil requires not only the right technology but also addressing the common problems that can arise during edible oil refining process. At Henan Glory Oils & Fats Engineering Co., Ltd., we specialize in providing advanced solutions for the edible oil refining industry. Our expertise helps you optimize the edible oil refining process, ensuring the production of pure, high-quality edible oils. In this article, we will discuss the most common problems in edible oil refining process and how our solutions can effectively treat these problems, enhancing both efficiency of edible oil refining and final product quality.

One of the common problems in edible oil refining process is foaming, especially during the degumming and deacidificating steps. Foaming can lead to edible oil refining equipment malfunction, increased oil losses, and reduced edible oil refining efficiency. To treat this problem, it is essential to monitor the temperature, acid content, and the amount of water used in the edible oil refining process. Regarding this problem, Henan Glory can provide you with advanced anti-foaming agents and optimized edible oil refining process control systems to effectively reduce foaming and improve overall edible oil refining equipment performance.

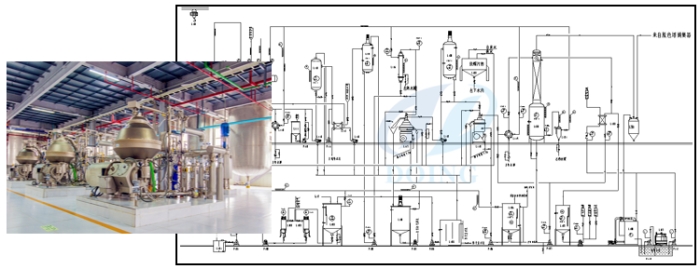

Degumming and deacidification equipment and process flow chart

Degumming and deacidification equipment and process flow chart

Impurities such as phospholipids, free fatty acids (FFAs), and trace metals can significantly impact the quality of the refined edible oil. They can affect the flavor, shelf life, and health benefits of the final product. A common treatment is to use more efficient filtration, adsorption, and decolorization techniques. In this regard, Henan Glory company has specially designed the most advanced edible oil refining equipment and filtration equipment, which help remove impurities more effectively, resulting in a cleaner and healthier edible oil.

Deodorization in the edible oil refining process is a critical step in removing undesirable odors and flavors from edible oils. However, poor deodorization can lead to edible oils that still have undesirable tastes or smells, affecting the final product's consumer appeal. The main treatment method to improve efficiency of deodorization is to maintain optimal temperature and pressure conditions. It is worth mentioning that Henan Glory Company specializes in the production of edible oil refining systems to ensure efficient deodorization by precisely controlling the temperature and vacuum during the edible oil refining process, thus ensuring that the resulting edible oil is odor-free and retains its natural flavor.

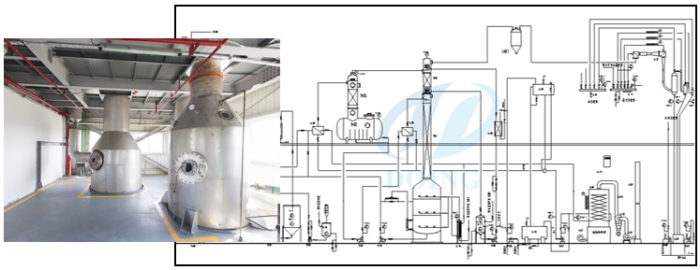

Deodorization equipment and process flow chart

Deodorization equipment and process flow chart

Loss of Oil is another common problem in the edible oil refining process, especially during the degumming, deacidificating, and deodorization stages. Oil losses can significantly reduce edible oil yield and impact the profitability of the edible oil production. To treat this problem, it is essential to optimize the edible oil refining process parameters and edible oil refining equipment design. Henan Glory can provide you highly efficient edible oil refining equipment that minimizes oil loss by improving oil recovery rates and reducing waste throughout the edible oil refining process.

Color is an important parameter for consumers when evaluating edible oils. Sometimes, edible oils can suffer from color degradation problem during the edible oil refining process, especially during decolorization or deodorization. This degradation may result in a dull or unattractive oil product. A common engineered treatment is the use of advanced decolorization systems that effectively remove pigments through the use of activated carbon or clay while maintaining the natural color and quality of the oil.

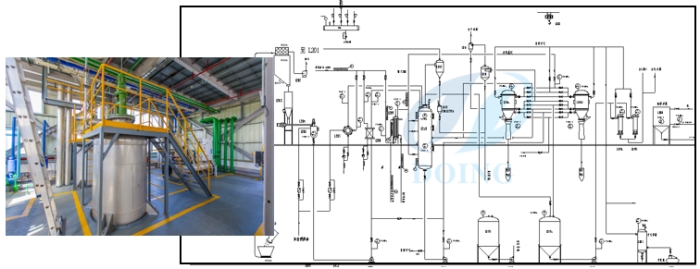

Decolorization equipment and process flow chart

Decolorization equipment and process flow chart

Oxidation is one of the primary causes of rancidity in edible oils, reducing the shelf life and quality of the product. It is essential to control the exposure of the oil to oxygen, light, and heat during the refining process. A common treatment method to prevent oxidation and preserve edible oils are to use systems that minimize the risk of oxidation, such as vacuum deodorization units, which prevents contact with oxygen and maintains the stability of the oil.

In summary, the quality and shelf life of refined edible oils can be significantly improved by treating these common problems with appropriate methods. If you are looking for advanced solutions, please feel free to contact Henan Glory. We are committed to providing high-quality edible oil refining equipment to ensure that your refined edible oil reaches the highest oil quality and standards.